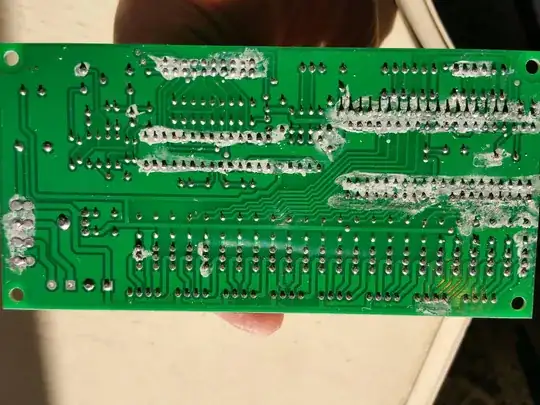

I am looking at this PCB I've got and these pads look terrible. It works, but this sure doesn't look right. What can I use to clean it up?

I am looking at this PCB I've got and these pads look terrible. It works, but this sure doesn't look right. What can I use to clean it up?

I would start with alcohol and a stiff brush, clean up the excess with some qtips. If that doesn't work you could try some of this, best to spray it outside though.

It's hard to say what that residue is. It could be flux left over from soldering or it might be mineral residue from water having evaporated off the board.

If it's flux, Isopropal Alcohol (IPA) followed by a rinse in hot water may remove it. Be sure to blow the water off the board before it has a chance to dry. Use a toothbrush to help the alcohol to loosen the deposits.

You can also use a commercial flux remover - they usually work very well.

If it's mineral deposits, you may need to try vinegar or a dilute solution of CLR (a commercial solution that removes Calcium, Lime, Rust). Be absolutely sure that you completely rinse the board off with hot water afterwards and then blow the water off the board.

I have also seen deposits like this left after boards have been soldered with Water Soluble Flux but not cleaned properly after soldering. However, that flux remains conductive and the board most likely wouldn't work properly if that amount of flux remained on the board.

Some readers may question my suggestion of rinsing the board with hot water and then blowing dry. This is still an industry standard method of cleaning PCBs fresh out of a wave-soldering system that uses Water Soluble Flux. For example, we use Kester AZ2331 flux in our wave-soldering system - this stuff is wonderful because it is so active (promotes soldering very well) and because it washes off the board so completely when it with hot water. Our surface resistivity meter simply shows no conductivity whatsoever whenever we test our boards for cleanliness after washing.

I never buy commercial flux remover, which would likely help you with your problem, rather I go down to a local discount beauty supplies emporium and buy a bottle of acetone and a bottle of alcohol (not the drinking kind) and mix in equal parts.

Use a squeeze bottle for easy application of your brew.