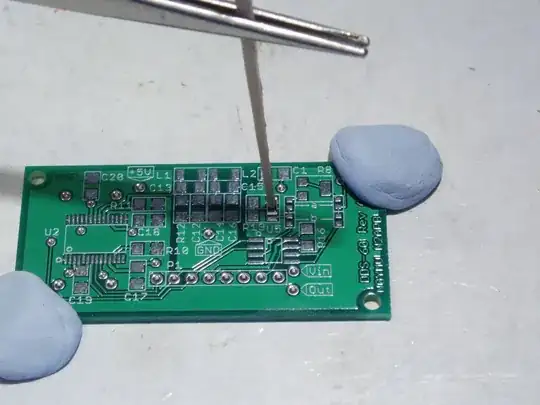

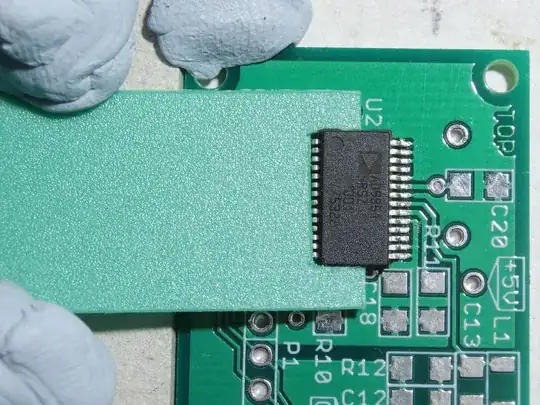

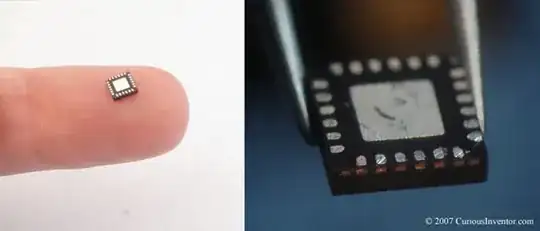

I go through this every time I have PCBs I need to populate with SMD parts, and this has become more an issue as pin spacings have gotten tighter, and my hands have become less steady with age.

So far I've modified some curved tweezers with a rubber band for grip tension, to help hold a component in place until 1 or 2 pins can be soldered. It works but it can be cumbersome. The clamping force needs to be very light, and it seems one slight tap with a sharp iron tip will still move it. I've also tried various glues, placing a pin drop of glue in the center of where a component would go.

That sometimes works, but all the glues I've tried either waste my time waiting for it to dry, or dry (skin over) too quickly when grabbing some more. Worse, too often even a pin drop of glue will spread onto the pads, and then I have to waste more time cleaning things up.

If I had my druthers, all SMD pars would come with peel off self stick backing. But anyway, suggestions would be welcome. It will be a long time and many test markets before anything I'm doing will be populated for me with pro pick and place machines.