I just assembled a board that I have created that basically acts as a breakout board for a MKL26Z32VFM4. Today, I am trying to get it to communicate over SWD so I can program the initial bootloader. I've never done anything like this before and this is basically an experiment for myself to see what it takes to go from datasheet to working device with one of these microcontrollers.

I have another microcontroller emulating the SWD interface and it might not be emulating it properly (I haven't yet actually counted the pulses to make sure it is using 50 pulses to initialize). In any case, the KL26 failed to respond when I held RESET_b low.

I decided to see if the processor was even starting, so I put the oscilloscope on the RESET_b pin when it was left floating to see what would happen. According to the datasheet, it is pulled up internally and during the boot sequence it is driven low until the processor reaches a certain state. It then releases the pin and sees if it is rising fast enough (KL26 family reference, 6.3.3). If it isn't it keeps the processor in reset mode.

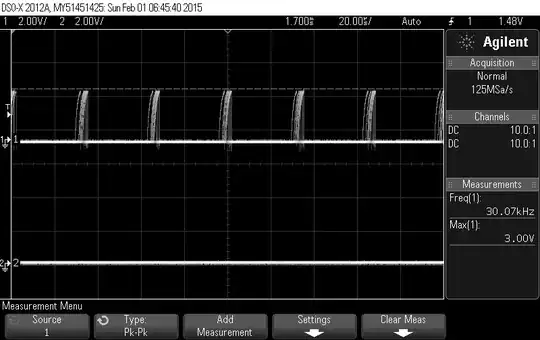

I see the following waveform on the RESET_b pin (pin PTA20):

This doesn't look right at all. I should see it just simply high, not making a nice RC curve between 0 and 3V at approximately 30kHz (it's really wiggly as can be seen).

My theory: It is somehow stuck in a boot loop since it is driven low quite rapidly.

I could put a resistor on the reset to raise it to 3.3V, but I'm curious as to why this is happening. There are possibly a few mitigating factors:

- This is my very first QFN chip that I have soldered by hand. I soldered it by tinning every pad, laying down flux, setting the chip on top, and then heating up a via-connected thermal pad on the back of the board for approximately 5 seconds while tapping the chip with tweezers. It appears to have soldered well and the 3.3V usb regulator seems to be working fine (at least the voltmeter and oscilloscope say so). It is possible that I have a void somewhere or a cold joint.

- There was an ESD incident when the device was powered off and not connected to anything. I touched it with both hands to lift the board from my breadboard and felt a slight shock. The regulator still works and the chip doesn't let out smoke or heat up when powered on, so I'm not sure what happened here and if it is a problem. I have 2 additional backups that I could use, but that would require assembling them. I swear, if this is the problem I'm going to buy an ESD strap right away (yes I'm assembling this in my apartment, on a computer desk, sitting on a carpet, and it's cold outside (i.e. low humidity inside)).

In any case, my questions are:

- How do I properly connect the chip for SWD? It's powered on, reset held low, and SWD connected to the appropriate pins, right? Am I missing something? My SWD program outputs 50 clock cycles, issues the SWD switchover command, outputs another 50 clock cycles, and attempts to read the IDCODE register.

- What could be causing this strange RESET_b behavior? Did I break something and have to start over?

EDIT

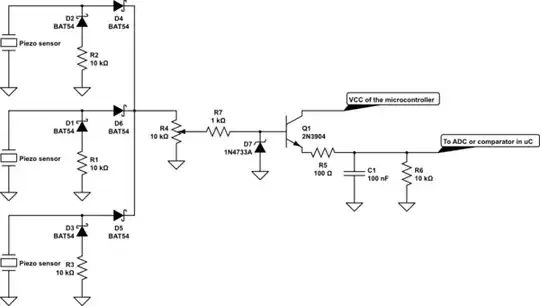

I have some additional waveforms from my programming attempt that might help. Clock frequency is 26Khz (KL26 says it can go up to 25Mhz).

Rise time on the SWD_CLK: 37nS (KL26 datasheet table 17 says this should be max 3ns...hmm)

My transaction: 50 pulses, 16 bit switchover command, 50 pulses, read IDCODE

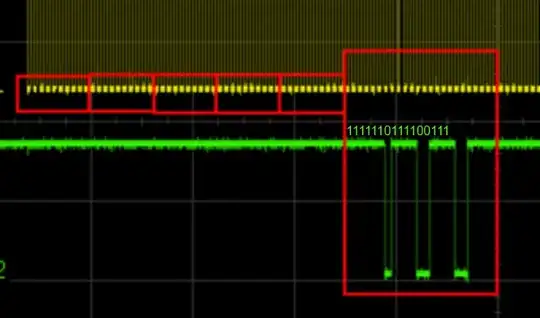

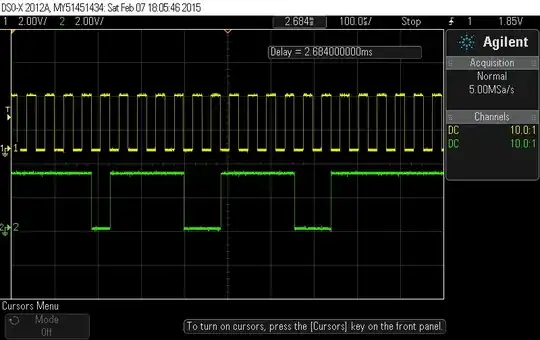

The switchover command:

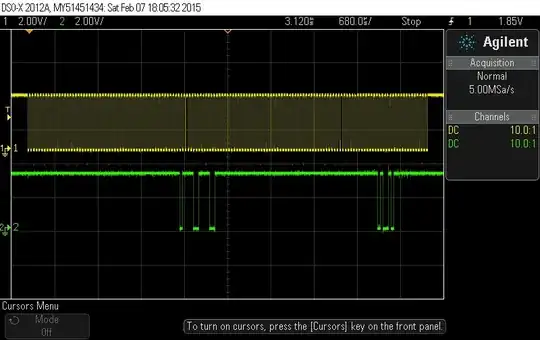

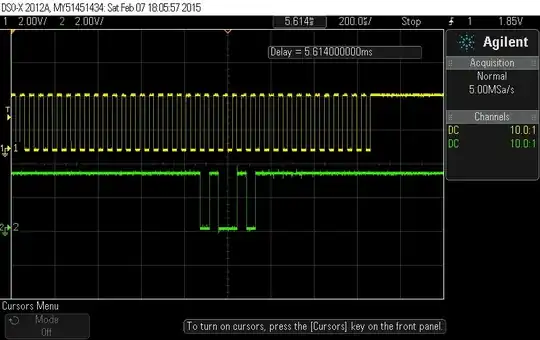

The read IDCODE command and lack of response from the KL26:

Edit 2

Enabling the DSE bit on the PCR register for my SWD clock decreases the rise time to 7ns, still above 3ns. It also causes a ring that peaks at ~3.7V (the line settles at ~3.2V).