Other answers here show a common way to allow a microcontroller to cause a contact closure (button press) within another device in an isolated fashion: use an optoisolator.

I have the reverse problem. I've got a distant unpowered button, and I want to know when it is pressed. I want to know this without risk of damaging my µC due to badness \$\gg V_{DD}\$ on the long wires running back to that button. If you want a mental model of the application, think of it as an electronic doorbell.

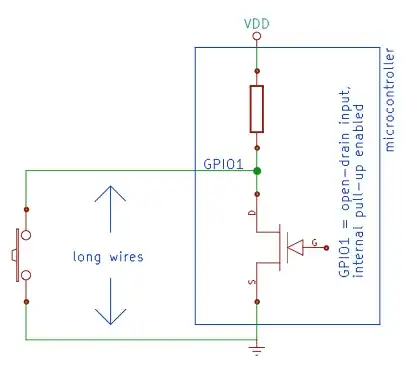

I already know how to sense the remote button press in an unprotected fashion:

I also know about the standard method of microcontroller input protection. (Zeners, GDTs, TVSes, MOVs, current-limiting resistors...) I was just hoping to be able to buy a 2- or 3- terminal blob with some combination of those components arranged, qualified, and quantified. I even dared hope that I could find a gang of N of them in a "firewall IC" for under $10. (4 ≤ N ≤ 10) I want the effect of going to the littelfuse.com homepage and saying, "Yes, I'll take all of that, and can you tie it up and put a bow on it for me, please?" Littelfuse seems to prefer that I buy a pile of discrete parts instead.

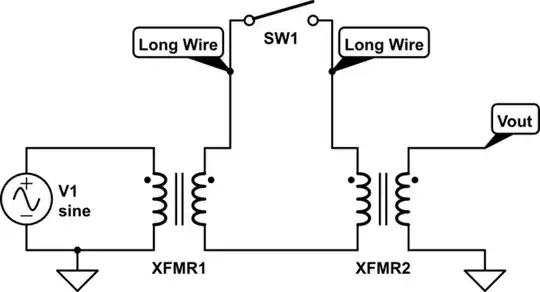

An optoisolator won't work here because it requires that I either power the remote end with a separate isolated power supply or give up some isolation by powering the LED side of the isolator from the microcontroller's supply.

I want it to work with just a raw contact closure. If there's any voltage coming from the button, it's either an application error that I wish to protect against (e.g. active sender rather than a dumb button) or badness per above.

The Infineon ISO1I813T is the closest thing I've found so far:

The problem is how many external components it requires. With the same number of components, I think I can probably come close to its effect with the standard method. The only thing I lose is isolation, and I'm not sure I really need that. All I'm certain I need is protection.

As a provisional goal, let's try to make it withstand at least an indirectly-coupled lightning strike. Somewhere between that and EMP-proof would be nice. :)