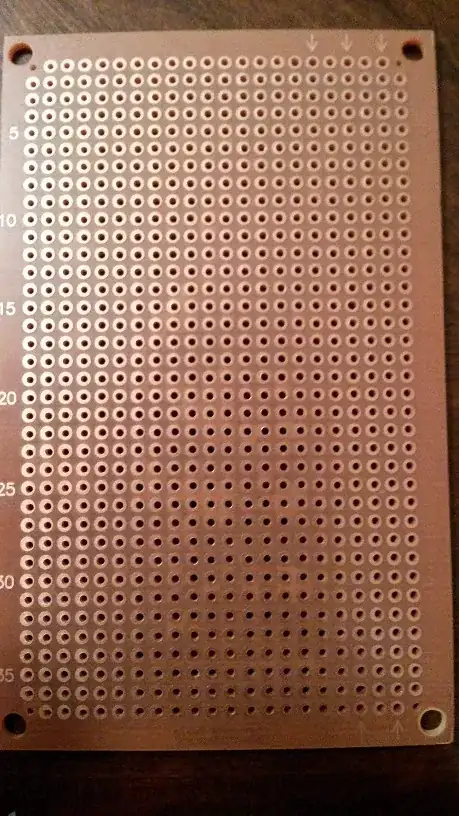

I have a PCB which has the perfect size for a project of mine, so I would like to use it if possible. However, the copper plating on the back side of PCB only surrounds the individual holes (that is, no holes are interconnected). See picture right here:

I find this strange. How can this be useful? I would definitely need some copper tracks with interconnected holes in there because some components need to be connected to each other. Am I supposed to make my own tracks somehow?

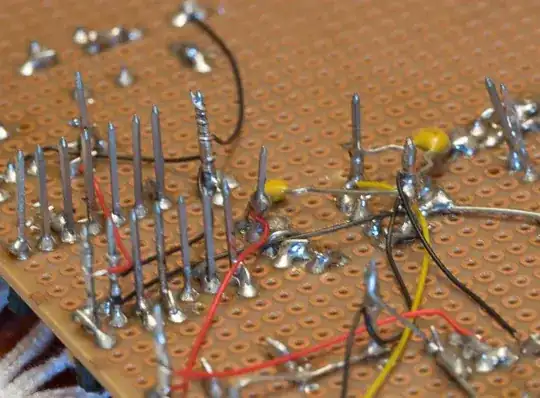

I saw some stuff online about people who would insert multiple wires in the same hole to make interconnections, but this seems undesirable. I'd rather avoid that if there is some way to make tracks.