I have an induction hot-plate that one day blew a fuse in my distribution panel when plugging it in. (With the obligatory smoke from the device of course)

On visual inspection, only the AC filter PCB shows obvious damage:

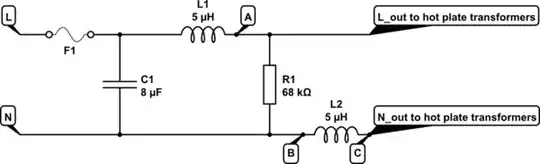

simulate this circuit – Schematic created using CircuitLab

(Note: R1 might also be 51kOhm (color codes are damaged), L1&L2 are 20.5 turns on a 1 inch yellow core.)

Description of Damage:

- The PCB between the right terminal of L1 (point A on the schematic) and somewhere from L2 (points B or C alternatively, hard to say with a torroid) is severely eroded from arcing.

- The casing material of resistor R1 is cracked and slightly blackened but the resistor is not "exploded" as one would expect from a overloaded resistor. It seems possible that R1 was simply in the arc path between the two inductances.

- That being said, the terminals of R1 are also blackened. (Maybe due to a "wandering" arc?)

Photograph of PCB:

Bottom of PCB is pristine.

Bottom of PCB is pristine.

Questions:

- Am I right to assume that R1 has no function other than to provide a safe discharge path for C1 e.g. when unplugged?

- If so, why is R1 not directly parallel to C1? It seems like an odd design choice to run the discharge through L1...

- Any idea what caused the arcing (presumably between the two inductor terminals)?

My gut reaction:

My gut reaction is that there is no real issue with the filter PCB itself, but that a problem from down the line only manifests here.

Since induction hot plates work with high-frequency, is it reasonable to think that a fault with the HF part sends HF back up the line? If so, with HF being blocked by L1 and L2 it jumps between points A and C.

I am surprised, however, that a gap of about 10 mm can be bridged which seems to suggest an unexpectedly high voltage.

(Note: down the line a 1200V (visually undamaged) capacitor is used in the HF part of the hot plate which suggests the maximum voltage that should occur is the circuit...)