An alternating current through a transmit coil induces an alternating voltage in a receive coil. The receive coil in a regular transformer is called the secondary winding and this receives about 97% of the magnetic flux produced by the transmit coil (primary) so, this sets the basic scene.

What you need to design is a transformer with a small airgap. Using ferrites is a good idea because then you can make the airgap shorter and actually direct the alternating magnetic flux to where it has to go - the higher the percentage flux received thtough the secondary, the more power you can effectively transmit to a receiving load.

However, when you have a situation where the flux coupled is a much smaller fraction (say 50%) you have to start to do tricks and one of those is operating the coils at several kHz to a hundred kHz and tuning the coils (they are inductors after all) with capacitors so that they resonate. What happens when the transmit coil resonates - you get current amplification into the coil and this boosts the magnetic flux and more flux is received (it may still be 50% coupled but, for a given stimulus of current to the primary tuned circuit, there can be double or more current in that actual coil).

This brings me to point out one of the things that you need to be wary of - if you have a highly tuned primary, off-load i.e. not interfacing with the load on the secondary, the terminal voltage of the transmit coil can create massive currents and bang, you coil fries. You have to have a mechanism that limits the current in the transmit coil and this can be a little sophisticated.

In a regular transformer, if a current is taken from the secondary this is reflected by a current in the primary that, in-effect, "forces" the secondary voltage to largely remain regulated. Not so when coupling is low.

You could short out the secondary/ recieve winding and you'll just find that the transmit winding current rises but doesn't go crazy like a regular transformer - this again is due to lack of 100% coupling and ultimately defines how much power can be transferred at a given distance and coil topology.

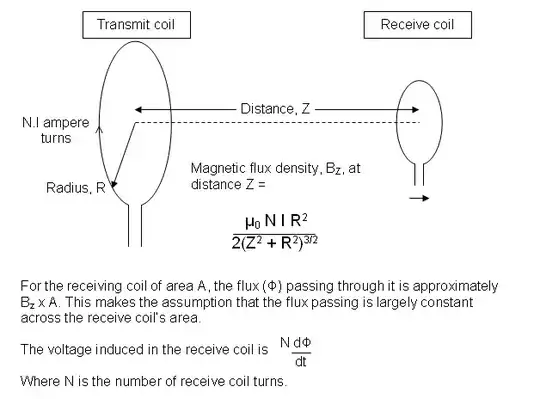

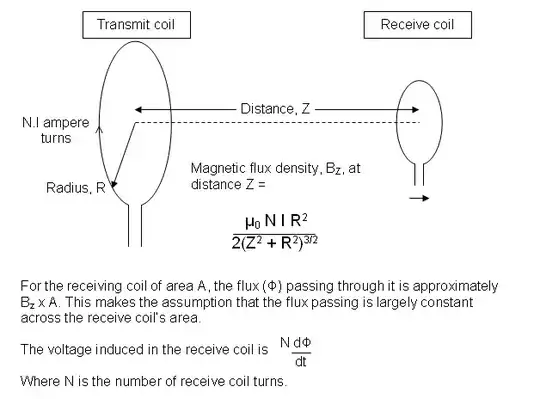

If you need the maths, here's a picture that can help: -

The above picture is for coils totally in air - clearly if you use ferrites to minimize the gap the flux received formula effectively reduces the Z dimension and, as the coils get very close (and the same diameter) you have a regular transformer. It's also worth noting that tuning the receive coil with a capacitor is also going to mean you can get more current out - I know it doesn't look this way but the receive coil with a physically parallel capacitor is in fact a series tuned circuit due to the way voltage is induced in series with the receive coil - when this happens the leakage inductance of the secondary/receive coil is totally cancelled out meaning the output impedance of the coil is only limited by the coils internal resistance.

Good luck and, if you get a chance let us know how you get on with your design. Part of my job is powering rotating electronics (stuff on jet engines used to collect data) and we have to throw a couple of watts across a sometimes sizable gap of up to 40mm with usually non-ideal coils so I have a personal interest.