I.e.  vs.

vs.

Would the reasons be similar to those answered here, but emphasized on unwanted capacitance, noise, and power issues?

I.e.  vs.

vs.

Would the reasons be similar to those answered here, but emphasized on unwanted capacitance, noise, and power issues?

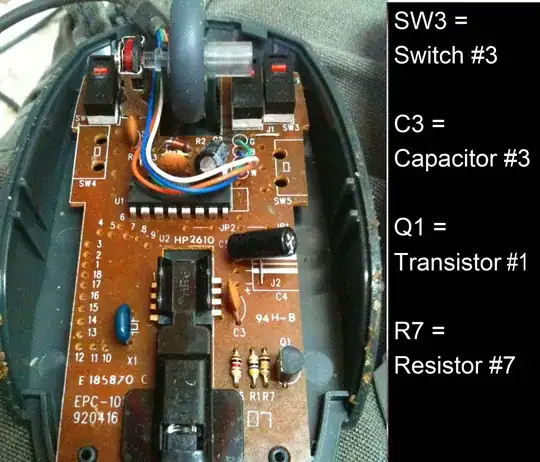

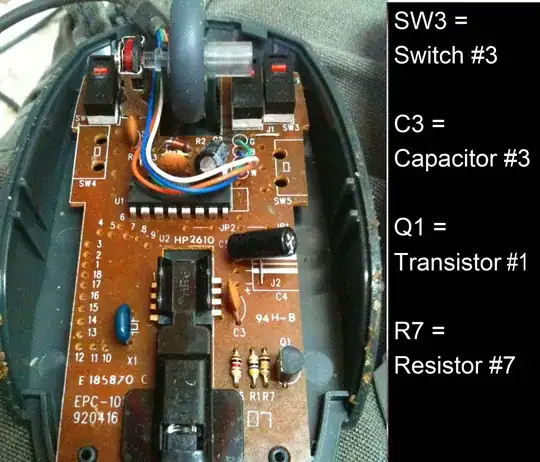

More and more components, a.o. microcontrollers, are only available in SMT (Surface Mount Technology), which don't have a 0.1" pitch. Adapter boards to go from, say, TQFP to breadboard exist, but become very inefficient if you need several of them, real estate-wise.

My rule of thumb is something like:

(a) Am I putting together something that is highly sensitive to parasitic induction and capacitance, such as a switching power supply or GHz radio transmitter or receiver; or do I need some IC that only comes in a fine-pitch SMT package? I don't have a choice. I am forced to use a custom PCB. (Sometimes you can get an off-the-shelf demo board or adapter board for just that one section, or make a custom PCB for just that one section, and prototype the rest of the system using a quicker and lower-cost technique).

(b) Am I rigging up a single quick experiment to test something for a few minutes? Use a solderless breadboard: it's the quickest. Alas, for longer-term use, or if you try to ship it any significant distance, wires and components inevitably work loose, causing frustration.

(c) Am I rigging up want to rig up one or two devices and expect to use it (sporadically or continuously) for over a month? Or do I expect it to still work after shipping it to another location? Use wire-wrap or soldered wires (or both) on some prototyping board (stripboard, perfboard, etc.). Alas, even though any one wire connection can be placed and soldered (or placed and wire-wrapped) in a few seconds, it seems to take a long time build each board (compared to custom PCB or solderless breadboard), and any human placing lots of wires will inevitably put some wires in the wrong place, causing frustration. (Many SMT devices can be used on such a board).

(d) Do I want dozens of identical devices, at minimum the total time and cost? Use a custom PCB. Alas, a custom PCB has much higher up-front costs, which eat up your savings in assembly time and in some cases part costs unless you make lots of them. Alas, a custom PCB usually takes longer to get the first functioning prototype than other methods -- often requiring 2 or more "spins" -- although, once production is set up, it's much faster and less error-prone per device.