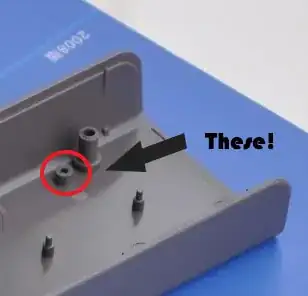

It seems obvious that square holes will have a somewhat wider tolerance for a range of screw diameters, which is handy for hobbyists who have an assortment of screws laying around.

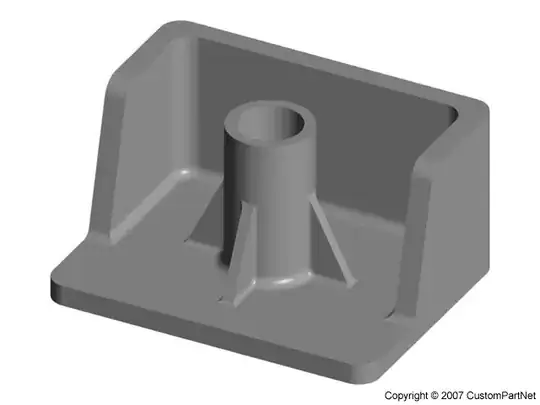

The screw has to forge a thread for itself, and that means displacing plastic. If the hole is round, then it works best when the screw has a fairly precise diameter in relation to that of the hole. The inner diameter of the screw has to be narrower than the hole, because the inside of the thread (the "valley") provides space for the plastic displaced by the "crest" during thread formation. If the plastic has nowhere to go, it is increasingly difficult to turn the screw. The post could crack from the pressure. Yet, the screw cannot be so thin that the outer thread diameter doesn't provide a solid grip; it will then easily strip the newly formed thread when tightened.

If the hole is square, then the screw thread's inner diameter can be exactly as wide as the the sides of that square, yet it will still fit without undue difficulty; the displaced plastic can flow toward the nearby empty corners of the square. Yet, the screw can still be as narrow as what would be acceptable for a round hole of a diameter that can be inscribed in the same square.