I bought this three phase rectifier from local store and it has rectangular connectors,

Now I need to make its package on the ARES, but I cant figure out how to create rectangular holes in the package.

I bought this three phase rectifier from local store and it has rectangular connectors,

Now I need to make its package on the ARES, but I cant figure out how to create rectangular holes in the package.

Forget rectangular holes!

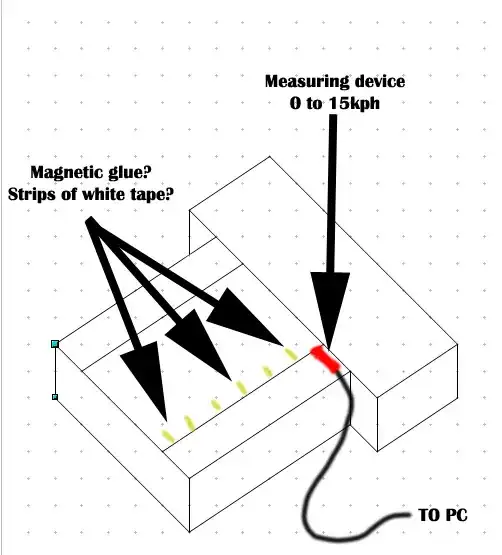

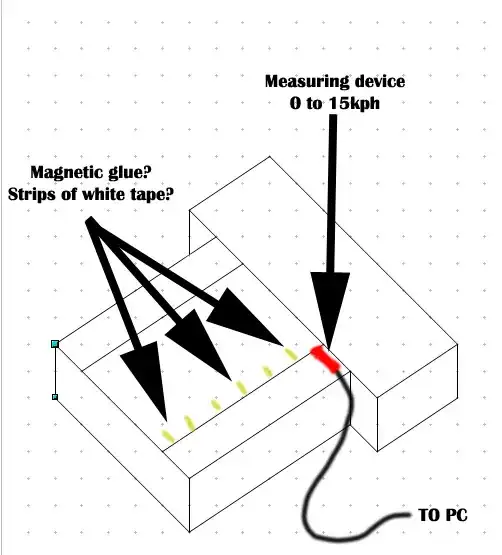

This kind of part is usually bolted to a heat sink, "dead bug style" (legs pointing into the air). The terminals do not go through a PCB; it is not a through hole part.

The terminals accept sliding "push on terminal" connectors.

(source of picture)

(source of picture)

To create a SLOT in ARES(PCB part of Proteus) requires 3 things. First is the ability of your PCB Fabricator to route out slots, and to know his minimum routing tool size. The jokes about rectangular drills are not very funny for someone asking for help.

Second, [C]reate a "PAD" in DILPAD mode. Make a name [ie SLT-100x40DP], then click OK. Next window you make the PAD dimension the outside dimensions of the copper for your slot. The drill hole should be .005" greater than the preferred or minimum routing tool of your PCB fabber. Smallest I see looking around is 0.5mm - .020", but you have to find out

Third, [C]reate a "PAD" in PADSTACK mode. Make a name, different than your DILPAD name [ie SLT-100x40], then select the DILPAD you created [ie SLT-100x40DP] in the Initial Style drop down box Under STYLE NAME select SLOTTED. In the SLOT box enter your slot dimensions [w=20th h=100th] and your PCB Fabber's slotting tool dimension[t=0.5mm]. Allow for copper plating thickness and round corners in deciding to the dimensions of your slot. On the right you can see what other layers you may wish to connect to, if you never do multi-layer boards, this info doesn't matter. You can always edit this later.

Click OK. iIn the list of available PAD STACKS your new plated slot [ie SLT-100x40] is available to use like any other hole or pad making a new package. Edit as needed. Finished slot info is placed on the Mechanical layer so be sure to include this layer in your Gerber .zip

Slots are handy, specially in high frequency applications- such as for a PCB mount antenna connector. Besides saving board space, solder has more capacitance than copper. A big hole could cause your project to function poorly. A ton of solder in a big hole is not an ideal solution.

However, that said above, slots do cost more than holes, and lots of the less expensive PCB proto places won't allow slots. So, find out the cost of a slot vs. a hole in your application, then make your choice.

To answer the actual question: "How do I create rectangular holes?":

In the PCB programs I've used (mostly Protel/Altium) there is no built-in way to specify rectangular holes,as few board shops have rectangular drills.

If you want non-round holes or other special milling on a board, you will have to discuss the matter with the board shop to determine if they can do what you want, and how they want it specified. (I've seen suggestions to mark the ends of a slot with a non-drillable hole size (perhaps .001"), so the board shop will have to consult you or a readme file to find out what you really want.)

Since you will be making this board yourself, using home-brew techniques, you just have to produce artwork that you will understand.