Engineers with a conscience don't let others use breadboards.

Oh, I know, it starts out easy, like any other drug. You're uncertain of yourself and instead of doing calculations, or even back of the envelope calculations you say to yourself " I'll do the easy thing, I'll breadboard it- I don't have to think too much and then I can move on". But that is the easy lie, sort of like using SPICE (but I digress) when you should be calculating \$g_m\$.

So you try it, perhaps your friends are doing it too, you want to fit in. And hey! it works, and you didn't have to spend too much time at it. But in doing so, you don't get the practise of doing those calculations, that skill never develops and eventually you end up being dependant upon the little suckers.

and then they turn on you

You're projects have started to grow, and get larger and say you want to show someone "the cool thing" you have been doing. And they want to touch it and you jump at them, not willing to allow them to touch your baby, your precious.

I was lucky when I started out. Someone gave me a breadboard to work with, and I now suspect that they did it on purpose. The thing is, this breadboard was damaged, and I wasted hours trying to get something running when it was a faulty breadboard. I didn't have that internal modelling ability, I didn't know what to expect, so I wasted time. After than once I never once used a breadboard again.

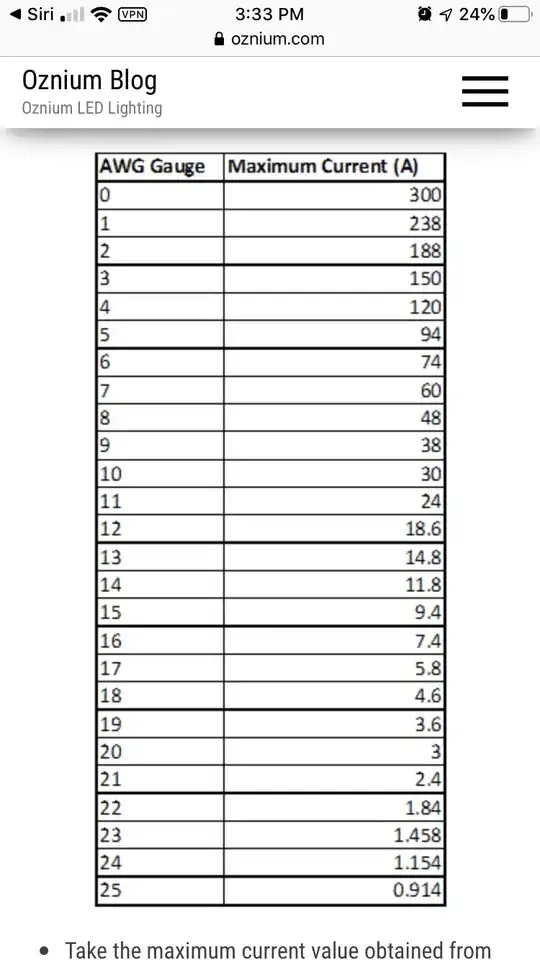

Using a breadboard is an easy way out, it's an addictive drug and if you persist you'll one day find yourself wondering " hmm, can I run One Amp those those little traces?" maybe you can. But the real question is, should you? with that much power, what happens when the board shorts out in behind (like they are wont to do)?

Listen, there are lots of ways to prototype things that take only a little more time than a breadboard that are semi-permanent, are not fragile, are smaller and more importantly allow you to build high performance circuits (be that high amperage or high frequency). Use protoboards or dead bug the circuit.

Being a little slower actually is a good thing, because you end up with something that can be handled, doesn't stop working the moment that someone sneezes and most importantly ... because you are going to put more effort into it, you learn to actually calculate before you commit. You end up learning more.

So kick the habit dead bug that sucker. You'll find that you get a better circuit by far.