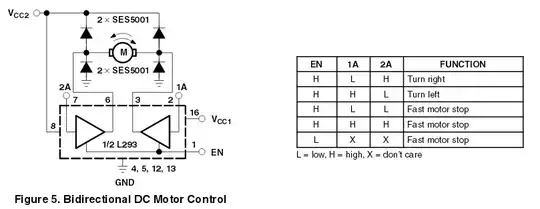

I want to drive an DC motor with ability both to change direction, and torque. Obvious solution: PWM + H-Bridge. I've been planning to use a PSoC4 for controller, and L293DNE for the H-bridge, which seems like a pretty standard choice. I've been pondering choosing some circuit to drive power supply with PWM, but reading the L293DNE datasheet, I saw it has 'Enable' pins - 1,2EN, 3,4EN.

Can I just drive the EN pin with PWM signal to achieve variable torque/speed, or will that cause problems, e.g. faster overheating or something like that? Are there other caveats I should consider (e.g. 'fast motor stop' instead of just 'power disconnected' resulting in some weird dutycycle:torque curve?) Should I add some more circuitry besides what's pictured if I drive 'EN' with PWM?