The effect of the Curie point is to change the skin effect. Skin effect is an AC effect (the depth of penetration of an AC current) and is approximated by:

\$\delta=\sqrt{{2\rho }\over{\omega\mu_r\mu_0}}\$

where

ρ = resistivity of the conductor

ω = angular frequency of current = 2π × frequency

\$\mu_r \$ = relative magnetic permeability of the conductor

\$\mu_0 \$ = the permeability of free space

As you can see, the skin effect is inversely proportional to the square root of the relative magnetic permeability of the conductor. So, if the permeability drops due to increasing temperature near the Curie point, the penetration depth increases.

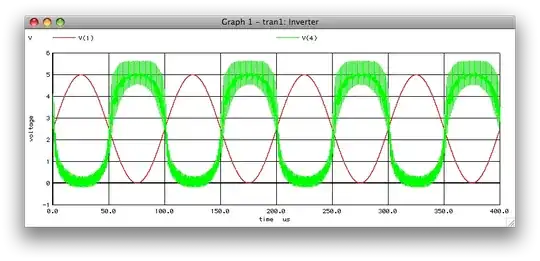

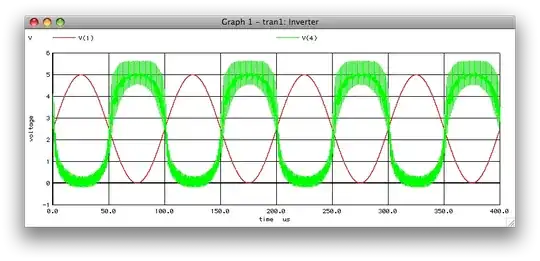

As shown in this source, the Metcal irons have a construction with an outer layer of metal on a highly conductive core as so:

When they are energized with a constant-current RF source, the current is shunted by the conductive core when the permeability is low (temperature too high) and thus the heating decreases. At low temperatures, the permeability is high and the current flows mostly through the resistive outer layer, causing a large amount of heating. Thus, the temperature is maintained near the Curie point.

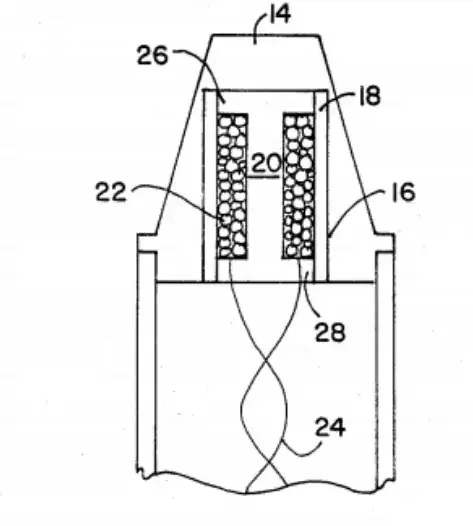

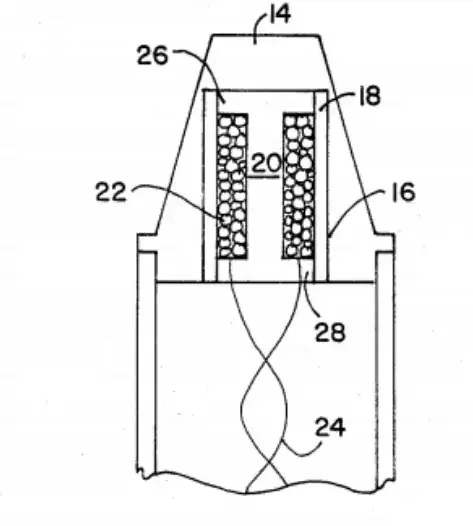

The actual physical configuration, as shown in the patent US 4,877,944, is apparently more like this:

The transformer configuration is used to match the heater impedance to the impedance of the coaxial cable feeding the hand piece.

It's not impossible to make such a device work at 60Hz, but few would want a soldering iron with a 150mm (6") diameter tip, it would make it difficult to solder SMT parts.