The LED assembly you have has 27mm diameter and only dissipates 1.5W, so it should have no trouble getting rid of heat by convection alone if it is placed vertically, as hot air rises...

At this level of dissipation, which is low, the PCB will probably be FR4 for cost, not metal core, so the thermal conductivity through the board should suck, unless the manufacturer drilled lots of vias. Cooling it from the back would thus be kinda dubious if there are no thermal vias.

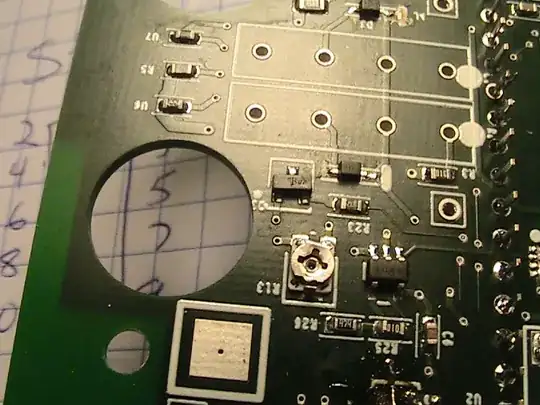

In fact, since I do not see any resistors or LED driver chip in the picture, I would guess they must be on the back. Obviously if there are components soldered on the back of the board, you won't be able to mount it on a heat sink, but for 1.5W as said above, it does not matter.

Therefore, some spray-on conformal coating should do the trick, but you must be sure it adheres everywhere, including the LED phosphor.

Since this LED assembly is certainly NOT CHEAP (£5 for 100 lumen? seriously?) if I were you I'd simply purchase 12V LED bulbs like these:

The bulb is glass, there is a glued-on plastic lens on the front, and the connections at the back look waterproof. If you manage to connect the 12V supply in a waterproof way, this should do the trick for you, and it is much simpler and cheaper than waterproofing your PCB.

Googling a bit, I also found submersible LED strips, so there should be many simpler solutions that will end up cheaper than purchasing potting resin...