I am considering implmenting an home automation system around my Raspberry Pi but I found the price and space requirement of inserting a Pi every place some control is required too much but the Cat5e cables required for this design is already installed during renovation. I have some PCF8574's, PCF8591's and SSRs lying around so is it possible to drive them using Cat5e cables?

All my Cat5e cables are already wired with TIA/EIA 568B pinout. They are part of my structural cabling and are not shielded, so higher line voltage is required. I am thinking sending power and I2C lines over the cable, with this pinout:

Pin 1 (Pair 1): SCL+

Pin 2 (Pair 1): SCL-

Pin 3 (Pair 2): SDA+

Pin 4 (Pair 3): +12V

Pin 5 (Pair 3): +12V

Pin 6 (Pair 2): SDA-

Pin 7 (Pair 4): GND

Pin 8 (Pair 4): GND

The power pin arrangement is same as 100BASE-TX PoE wiring so power rating will be the same too, and using of bidirectional differential signaling is found in 1000BASE-T which requires Cat5e.

Original I2C SCL and SDA lines are derived into two bidirectional differential pairs at TTL levels (the open-drain is not kept on the wire, but restored in the line termination/level shifting device that I am designing)

Any suggestion on that? Also, which chip should I use to convert I2C lines to the differential signalling? Please suggest chips with DIP through-hole option to me. I do not know how to handle SMT stuff.

EDIT

I found this chip, SN65LBC180, is it a good choice? How to wire it into a bidirectional unit? How to shift level (it is a BiCMOS part requiring TTL level but Pi drives at 3.3v CMOS levels) and make it open-drain-compatible?

EDIT 2

Commenters suggested RS-485 which appeared acceptable to me, but still the two differential pairs are required to be bidirectional and only two bidirectional differential pairs only. I am repurposing existing Ethernet cables.

EDIT 3

Since someone brought it up, I cannot use CAN. There is no way I can fit CAN onto RPi without sacrificing anything (SPI is occupied by a touchscreen, so no SPI to CAN converter)

I am aware of the limitation of I2C PHY so I am essentially trying to fit 1000BASE-T PHY to it - bidirectional differential signaling for SCL and SDA signals, but on top of that runs I2C protocol.

EDIT 4

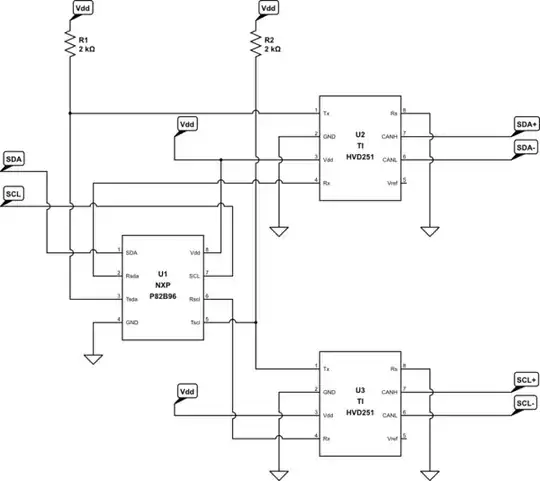

A new chip came to me: NXP P82B96 which splits I2C into 4 unidirectional lines, which in turn can be used to feed into SN65LBC180 through opto-isolation (Pi-side only) to form a 8-pin long-distance-ready signaling. Now I just need to figure out how to get power through the wire, or how to determine if the bus is sending and make the pairs bidirectional.

EDIT 5

From the suggestions of answers, I think I need to change the power pinout a little:

Pin 1 (Pair 1): SCL+

Pin 2 (Pair 1): SCL-

Pin 3 (Pair 2): SDA+

Pin 4 (Pair 3): +5V

Pin 5 (Pair 3): GND

Pin 6 (Pair 2): SDA-

Pin 7 (Pair 4): GND

Pin 8 (Pair 4): +12V

I2C differential signaling voltage is TTL. The +5V over pair 3 comes from the Pi, unbuffered but fused. The +12V over pair 4 may not be present is only used to drive some high-power devices. If needed the device may use its own power supply and leave both rails hanging unconnected or supply its own higher voltage but use the 5V rail.

SCRATCH THAT

Pinout is still my original design, which is 802.1af compatible.