I am thinking about building a(nother) wearable LED jacket project. The basis will be 60 LED/m WS2812B strips, around 2048 pixels, for a peak possible current draw of just under 125A. In reality I would never run full-white patterns, so count on a peak draw of maybe a quarter of this.

That's still a lot of current and I'm trying to think of a good way to distribute it to the ends of the strips. In my experience with other projects, each strip needs to be directly connected to power and the power bus needs to be very low resistance so voltage drop doesn't cause "reddening" of the strips that are connected at the end furthest from the battery.

I'm having difficulty thinking of a design that is a) high current capacity, b) flexible c) "neat" enough that I don't have exposed wires snaking around and d) field-repairable.

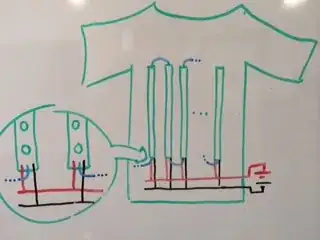

Here is a rough schematic so you get an idea of the orientation of the strips (red and black for +ve and -ve, blue is the signal wire which "snakes" up and down the strips):