I'm a hobbyist developing a hybrid power switch (electromagnetic + solid state) for a resistive electric stove (8kW max) top. I have a profoundly autistic, disabled adult in the house and I need a fairly specialized system to automatically shut off the stove if the kitchen is vacated for any reason. It also requires a code to enable it. And there are a few other "features." We've kept the breakers off for years, but things are changing so that is no longer acceptable and we need to reactivate the stove now. But with safety features customized to our special needs here.

The entire system is in two physically separate parts. One is the control panel -- battery powered only and placed less than 2 meters away from the hybrid switch system. A signaling method with very low false positives will be used from there to the hybrid switch micro. The hybrid switch micro uses a MOC3023 to control an EMR and a MOC3063 to control a pair of SCRs (I prefer a pair of these over a TRIAC for several reasons.) Unless I find a better way, there are two sets of these, one for each split. The SCRs are used ONLY for a few cycles, with the EMRs once engaged no longer requiring the SCRs until shutoff.

The problem is in supplying power to the sealed (plastic) module that contains the hybrid switch optos and micro. That part of the switching system is buried into a counter/wall area and needs to be self-powered from the 220VAC split phase system it switches. No batteries, etc. I like transformers, but the weight and bulk put extra risks in the work ahead and will also complicate other applications at a later date. So I would like to resolve this issue now with a transformerless system.

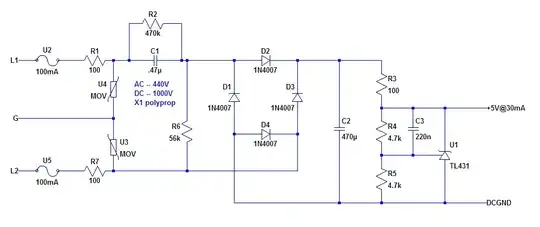

There are quite a few schematic pages but I'm posting just the preliminary transformerless power supply section above. I'm most concerned about C1. I gather it should be an X class capacitor. If it fails "short," the only protection I've got will be the 100mA fuse. I'm also ill-informed about MOVs and their correct specification for an application like this. And there probably are areas where I'm ill-informed that I don't even know about. Regardless, I've been "tasked" by family to "solve this stove problem" and solve it I will do. So there is no stopping that. The only question is about getting it done with risks reasonably mitigated.

I already know the advantages of galvanic isolation. A CHEAP COTS solution that has small physical volume and is designed for delivery of 5V in the area of 30-50mA would be interesting. Price and physical volume and weight are important and so is total dissipation. I want the supply and the load together to be under 1 watt total. That can be safely ensconced in a cavity. I also hope to put the micro and the rest (not shown) on this same board in SMT to keep it all as small as I can. But I could sacrifice that hope.

Technical comments about safety are very much appreciated. Bear in mind I'm solving an unusual set of requirements. I have approached local stove-top sellers, and a few of the national manufacturers, about their units. Some have disabling modes -- but the way they work doesn't help. I have researched other options and I believe I may be stuck doing some part (or all) of this. I have already built and tested the hybrid relay system, with optos, using a COTS power supply and it appears to work as well as I'm able to judge it.